E+S slide rail systems available from AGD

E+S invented the first trench shoring systems in Germany in the 1950s. They were the first company to design the slide rail system which facilitates quick and easy installation of small cofferdams and excavation pits up to 9 m depth.

AGD have just installed their first slide rail excavation pit and are now offering the system for sale or hire nationwide throughout the UK & Ireland with a hire installation service with skilled operatives if required.

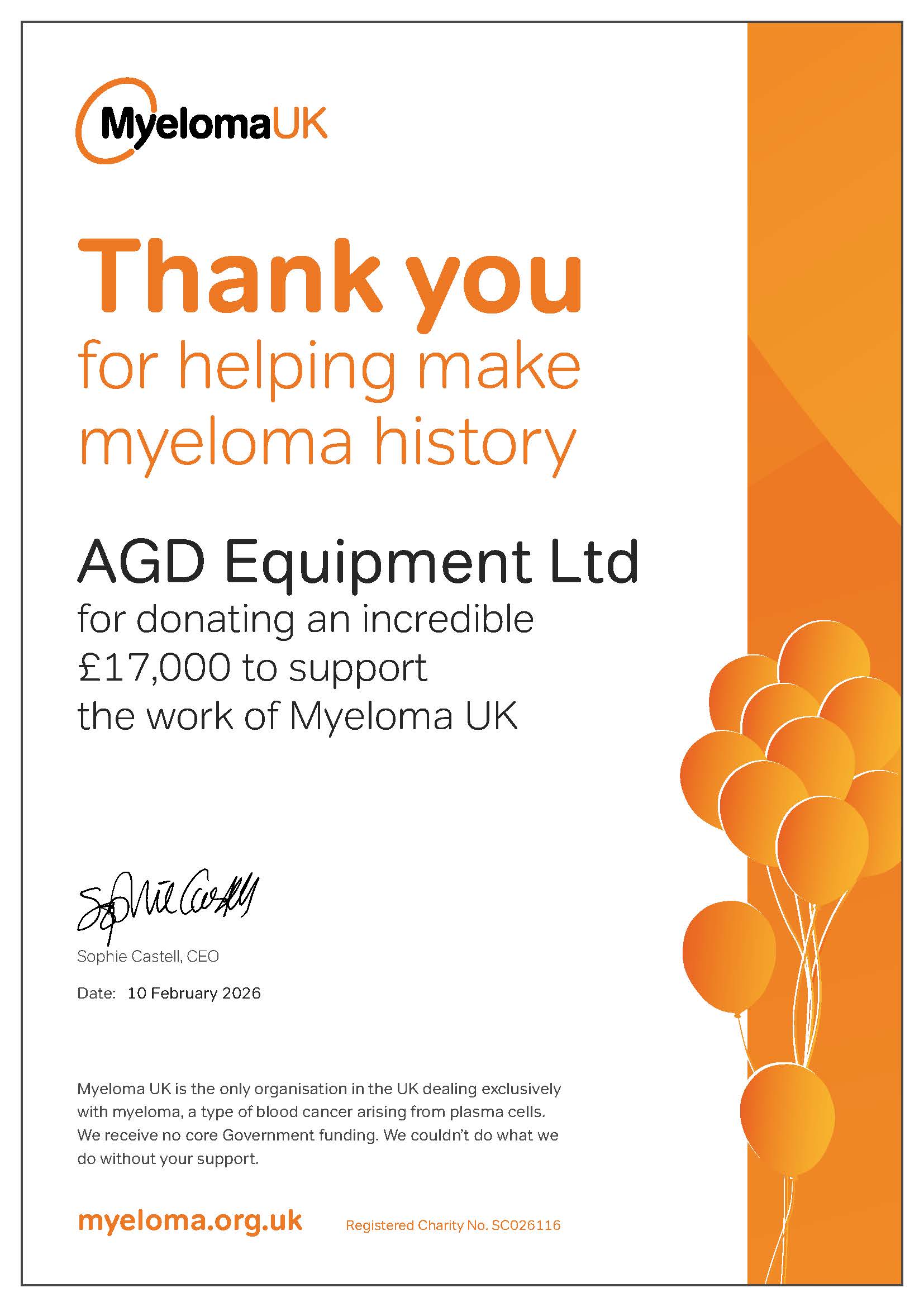

AGD crane raises money for cancer charity

Our pink telescopic crawler crane has had a busy year raising money for Myeloma UK.

Here are some photos of it working for our long standing customer Land + Water on the Tideway project in London.

New depot opened in Ireland

We've opened a depot in Portadown to service the whole island of Ireland. Geoffrey Burns has joined us as Regional Manager and brings with him a host of knowledge of the trench shoring and sheet piling sectors.

Business has started well with a number of trench boxes going out to various customers. We're also offering slide rail trench shoring, EMV and sheet piles, plastic sheet piles, crawler cranes and piling rigs for sale and hire.

Contact Geoffrey for any enquiries you may have and please stay tuned for more news as the business grows.

Muller MS-48 HFV crane suspend vibro installing 1800 mm diameter tubes in Cork

Our brand new Muller MS-48 HFV vibro in busy installing 1800 mm diameter tubular piles for a combi-wall at Ringaskiddy in Co Cork for Ward & Burke.

The 1000 hp stage V power pack delivers plenty of power to deal with the hard soil conditions.

Click on the link to see a video of it in action.

Dredging on the River Tyne

Rarely seen these days but we still have the equipment and specialist skill to supply crawler cranes with clamshell grabs.

Here you can see us dredging the River Tyne with one of our Sennebogen 650HD, 50 tons capacity crawler cranes, supplied with operator and banskman.

AGD - your one stop shop for crawler cranes and piling equipment.

One stop shop piling project delivered at Barby

AGD has delivered it's first one stop shop sheet piling project for A Williams Building Services on a project in Barby, Warwickshire.

We arranged the sheet pile design, supplied 9 m long TKL601 sheet piles and hired an RTG RG16T telescopic leader rig with operator and banksman to the project.

The sheet piles were being installed into hard soils and so we used the RTG to first pre auger and then an MR150AVM vibro to drive the piles to finished level.

Access on to the small site wasn't easy but all in a days work for #TeamOrange, your one stop shop for your piling projects.

AGD appointed distributor for Greenwall Plastic Sheet Piling

AGD have been appointed UK & Ireland distributors for Greenwall plastic sheet piling.

Vinyl chloride (commonly called PVC or Vinyl) together with the Co-Extrusion manufacturing process give Greenwall sheet pile significant advantages and mechanical characteristics such as:

- Competitive price

- 100% environmentally friendly

- Made from 85% recycled plastic

- Durability

- No toxic surface treatment

- No maintenance required

- Resistance to corrosion and salt deposits

- UV resistance

- Impact resistance

- Reduced weight

- Greater safety on the construction site

- Easy handling-transport

- Available in different colours to suit the environment

- Perfect for ponds, fishing & golf course lakes, canals, rivers, broads, waterways, reservoirs, railways, roads and a host of other applications

AGD are also able to offer design, and rental installation service with operators and piling hands.

Contact our sales dept for further info and pricing.

Click on the link below to see a video of a project where plastic piling is been utilised along a river.

AGD exhibit at Bauma with sister company Terra

A brand new RTG RG19T telescopic leader rig in our livery was on display, fitted with an MPZ press.

Terra had an array of equipment to see including Muller crane suspended and excavator mounted vibros, Greenwall plastic piles and trench shoring equipment.

The show was well attended and we look forward to following up with all of the customers who took time to visit us.

Brand new Sennebogen 6113E sold to Trident Lifting

Brand new Sennebogen 6113E, 120 tons capacity telescopic crawler crane sold to Trident Lifting Solutions. Pictured here working in Berkshire for their parent company Statom Group.

Fully electric 15 tons Trio City Crane launched by Marchetti

Fully electric 15 tons Trio City Crane launched by Marchetti

We are pleased to share the news that a brand new fully electric model 15 tons capacity all terrain city crane has been launched by Marchetti.

The Marchetti Trio 0E is equipped with rechargeable batteries, has a range of 60 miles plus 8 hours working time. It can be charged on an ordinary car charger. The compact design coupled with its environmentally friendly power source makes it perfect for city centre or inside building working. At the same time fully future proofing your NRMM / ULEZ compliance. Saving both carbon emissions and fuel costs. Excellent specifications.

See it on stand number FS.1004/14 at Bauma in Munich during April 2025. Contact us for tickets if required.

Contact any member of our sales team for further information.